Italy, according to ENEA studies, is one of the leading countries in the world for the number of seismically isolated structures. Precisely it appears to occupy the fifth place in the world rankings after Japan, China, Russia and the USA. It is also the first European State for the application of systems of insulation and energy dissipation of buildings, bridges and viaducts. Nevertheless, there is a need for constant and greater awareness at a socio-cultural level; just think that, again from ENEA studies, there are many critical situations: over 70% of the buildings would not resist the earthquakes that can hit them, including schools, hospitals and many other strategic structures. The idea of allowing the building to move relative to the ground had already been intuited and applied in antiquity: in the work of Pliny the Elder 'Naturalis Historia', it is said that the temple of Diana in Ephesus, dating from the 6th century BC, that is one of the seven wonders of the ancient world, had been built on a layer of clay mixed with coal and ash, so that, in the event of an earthquake, the seismic action would not be transmitted entirely to the building (as the structure could undergo horizontal movements with respect to the ground). The same technique had also been applied in numerous other temples located in Greece and in its colonies of the Black Sea and Magna Graecia. On the same principle the current seismic isolation techniques are based in which the insulation at the base of the building is no longer represented by sand, clay or coal but consists mainly in the introduction, between the substructure and the superstructure, of particular appliances called "elastomeric isolators" or "seismic isolators" which, thanks to their modest horizontal rigidity, decouple the movement of the structure from that of the ground and dissipate the greatest amount of energy released by the earthquake. In our country since 1627, after the severe earthquake that struck Campania, anti-seismic construction rules were established but the official introduction of specific legislation for seismic isolation applications dates back to not many years ago, precisely after the Molise earthquake of the October 31, 2002, with the issue of the OPCM 3274/2003 which made possible the use of seismic and dissipative isolation systems without the passage of the long procedure for ministerial approval and introduced in Italy also the obligation of the semi-probabilistic method at the limit states for buildings in seismic areas. After the L'Aquila earthquake of 6 April 2009, the NTC 2008 entered into force definitively, but subsequently the UNI EN 15129: 2009 - 'Anti-seismic devices' from 01/08/2011 became predominant with respect to the indications contained in Chapter 11 of the Ministerial Decree 14/01/2008. Currently with the release of the new Technical Regulations for Construction with the Ministerial Decree 17/01/2018, the text of the specifications of UNI EN 15129 is recalled, thus realigning concepts and procedures to the harmonized European standard translated into Italian in 2012.

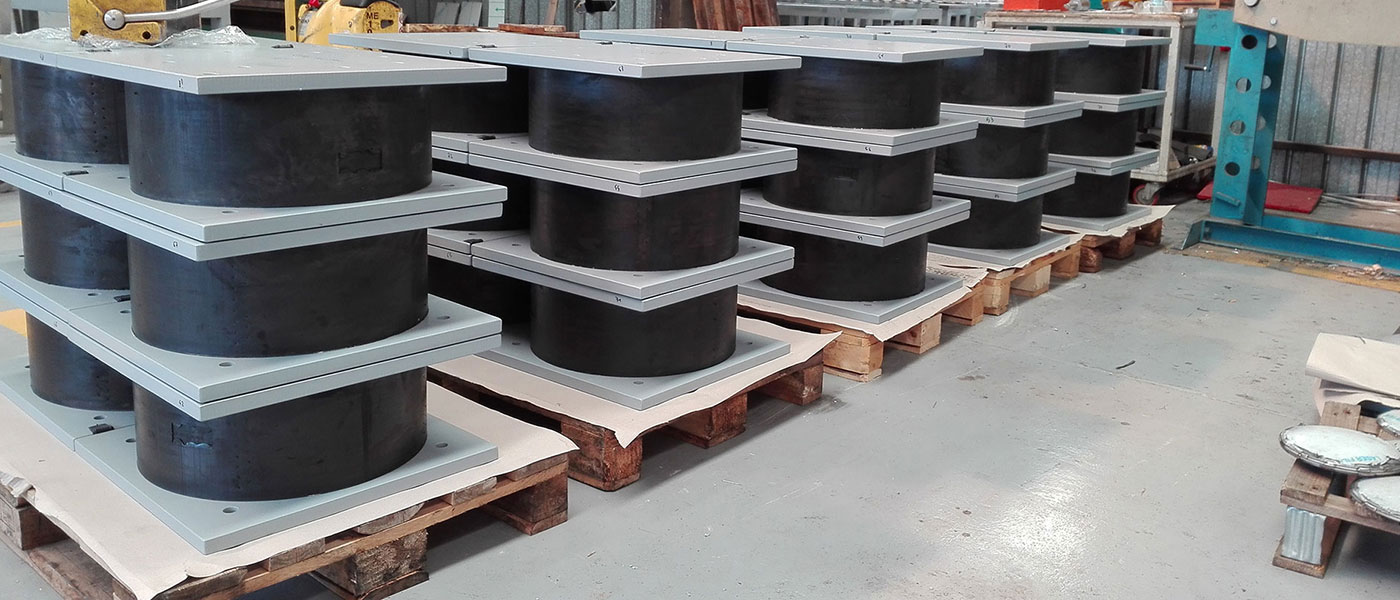

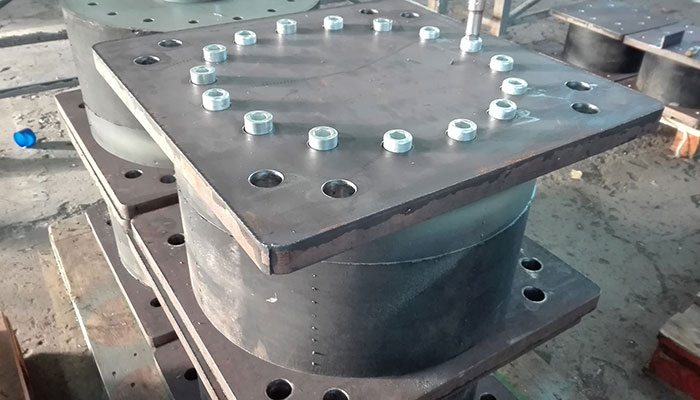

Elastomeric isolators are devices, generally with a circular plant consisting of layers of elastomer alternated with thin internal steel plates, joined together by a vulcanization process. The internal laminations have the purpose of confining the rubber itself. As mentioned above, due to their modest horizontal stiffness, elastomeric (or seismic) isolators for bridges/viaducts/buildings decouple the movement of the structure from that of the ground and dissipate the greatest amount of energy released by the earthquake. They must be characterized by a high horizontal stiffness in the case of small displacements of the structure (bridge/viaduct or building) to prevent movements under non-seismic loads such as the wind. The horizontal stiffness is lowered in the event of large displacements, such as those caused by earthquakes. The vertical stiffness must, however, be high to support the load of the superstructure. The values of stiffness are determined by the geometric properties of the isolator and by the characteristics of the elastomer use.

The properties of the elastomer are in compliance with the provisions of the European legislation concerning the elastomeric isolators, the EN 15129. Three different types of rubber compound are used according to the design requirements:

- Compound H (Hard) which has a shear modulus G = 1.40 MPa and a damping (energy dissipation capacity) equal to 14-16%

- Compound N (Normal) which has a shear modulus G = 0.80 MPa and a damping (energy dissipation capacity) equal to 12-14%

- Compound S (Soft) which has a shear modulus G = 0.40 MPa and a damping (energy dissipation capacity) equal to 10-15%

The seismic isolators at the top and bottom are provided with circular steel plates, called connecting plates, which are coupled, by means of a central pin, to the upper and lower terminal plate (square shape).

The attack on the superstructure may be different depending on the nature of the superstructure of the bridge/viaduct:

Steel structures

The elastomeric isolators are joined to the superstructure of the bridge/viaduct by screws passing through holes prepared by the manufacturer of the metal structural work or through threads provided in the welded counterplate or made integral to the main structure, always the responsibility of the carpentry supplier.

Each isolator is provided with an identification plate that specifies the characteristics of the device:

| Shear Modulus | Horizontal Stiffness | Vertical Stiffness | Damping | Seismic Project Displacement | Vertical Load to SLU | Vertical Seismic Load | Horizontal Load |

|---|---|---|---|---|---|---|---|

| G | Kh,eff. | Kv | ξ | dEd | NSd,max | NEd,max | Hd |

| MPa | kN/mm | kN/mm | % | mm | kN | kN | kN |

Approval tests (ITT) and factory production tests (FPC) must be carried out in accordance with the provisions of the EN 15129 standard, both dynamic and static, with constant frequency and cycles of increasing amplitude, with variable frequency and with varying temperature, in order to evaluate the variations in stiffness and damping.

Approval tests (ITT) and factory production tests (FPC)